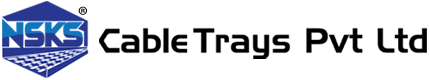

Ladder Cable Trays

Our Ladder cable trays are made up of high-quality materials, hence it is bound to have a very long working life. Our ladder cable trays are made with high-grade MS & GI coating that works very well with high resistance.

Accessories

Ladder Cable Trays

Ladder cable trays are a typical kind of cable tray that gets constructed by joining two longitude channels with supporting horizontal rungs. The usual materials used for making Ladder cable trays are aluminum, FRP, or stainless steel that comes along with hot-dipped galvanized, epoxy, pre-galvanized, polyester, or powder coated surfaces. Due to the strong structure, the ladder cable trays provide complete protection from the high pressures. The primary use of the Ladder cable trays is in power plants or paper mills for laying power cables or control cables.

Key Features

- High loading capabilities

- Longer life of service

- Air ventilation properties as the ladder is very spacious

- Suitable for multiple locations except elevator shafts

- Strong and robust structure that allows laying cables of different sizes

Types: of Ladder Type Trays

1. Bolted Rung Ladder Type Tray

These ladder types are commonly used and are available in multiple specifications. The bolted rung ladder type tray is primarily designed to hold all the power cables and electric cables. These are durable, have high strength, and also corrosion-resistant.

2. Welded Rung Ladder Type Tray

As its name suggests these are a type of ladder tray made up with the use of welding methodology. These are reliable and can perform well in harsh environments. Designed to support the cable system, these are highly reliable to keep it stable.

Technical Specifications

Material: Pre-galvanized steel, Hot-dip galvanized steel, Stainless steel

Width Range: 150mm to 900mm

Height Range: 75mm to 150mm

Length: 3m standard (custom lengths available)

Load Capacity: Up to 150kg/m depending on configuration

Rung Spacing: Standard 300mm (customizable)

Finish Options: Pre-galvanized, Hot-dip galvanized, Powder coated, Stainless steel

Compliance: NEMA VE 1, IEC 61537, BS EN 61537

Technical Specifications

Material Finish Options

| S.No | Material Finished | Specifications | Recommended |

|---|---|---|---|

| 1 | Pre-Galvanized | As Per Specifications | Indoor |

| 2 | Hot - Dip Galvanized | As Per IS 4759,2629, 2633 | Indoor & Outdoor |

| 3 | Powder Coated | As Per Specifications | Indoor |

| 4 | Stainless Steel | As Per Specifications 304, 316. | Indoor & Outdoor |

| 5 | Aluminum | As Per Specifications | Indoor |

Note:

- • R means regular sizes which used in the market

- • NR means not regular size production is done as per customer requirement

- • NA it means Not Available or likely to be used in the market but as per customer requirement, we supply.

Width of Ladder Type Trays

| S.NO | Thickness | Depth | 100 | 150 | 200 | 300 | 450 | 600 | 750 | 900 | 1000 | 1200 | 1500 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 1.6 mm | 50 MM | NR | NR | NR | NR | NR | NA | NA | NA | NA | NA | NA |

| 2 mm | R | R | R | R | R | R | R | R | NA | NA | NA | NA | |

| 2.5 mm | NR | NR | R | R | R | R | R | R | R | R | R | R | |

| 3 mm | NR | ||||||||||||

| 2 | 1.6 mm | 70 MM | NR | NR | NR | NR | NR | NR | NA | NA | NA | NA | NA |

| 2 mm | R | R | R | R | R | R | R | R | NA | NA | NA | NA | |

| 2.5 mm | NR | R | R | R | R | R | R | R | R | R | R | R | |

| 3 mm | NR | ||||||||||||

| 3 | 1.6 mm | 100 mm | NA | NA | NA | NA | NA | NA | NA | NA | NA | NA | NA |

| 2 mm | NR | R | R | R | R | R | R | R | R | R | R | NA | |

| 2.5 mm | NR | NR | NR | NR | NR | NR | NR | NR | R | R | R | NR | |

| 3 mm | NR | ||||||||||||